Description

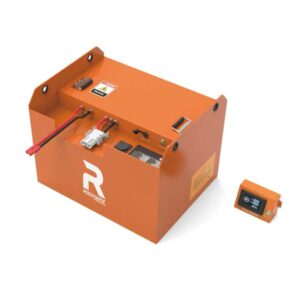

Our lithium battery manufacturer presents the 48V 500Ah LiFePO4 Forklift Battery, a high – capacity, long – lasting battery perfect for OEMs, ODMs, and wholesale buyers in material handling.

Key Features:

- High Capacity & Energy Output: With a nominal capacity of 500Ah and an energy output of 24kWh, it allows forklifts to operate for long periods without frequent recharging.

- Extended Cycle Life: Engineered for over 3500 cycles at 80% Depth of Discharge (DoD), reducing long – term replacement costs.

- Advanced Safety Features: Equipped with a smart Battery Management System (BMS) that guards against overcharging, over – discharging, and short circuits.

- Durable Construction: A sturdy metal shell with an IP65 rating makes it resistant to dust and water, suitable for tough working conditions.

- Flexible Communication Options: RS485, CAN – bus, and 4G capabilities enable real – time monitoring and seamless integration into fleet management systems.

Product Description:

The 48V 500Ah LiFePO4 Forklift Battery is expertly designed to supply reliable power for modern material handling. Operating at a nominal voltage of 48V, its 500Ah capacity results in an energy output of 24kWh, ensuring efficient long – term operation.

Key Specifications:

- Nominal Voltage: 48V

- Energy Output: 24kWh

- Dimensions: Approximately 800mm x 600mm x 500mm

- Weight: Approximately 350 kg

- Operating Temperature Range: Charging at 0¡ãC to 45¡ãC; Discharging from -30¡ãC to 50¡ãC

This battery supports continuous discharge currents up to 50A and peak discharge currents up to 100A, making it ideal for high – performance forklifts. Its long cycle life reduces replacement needs and overall operating costs. The natural cooling system maintains optimal performance without extra cooling.

For OEM and wholesale customers, the battery’s support for communication protocols like RS485 and CAN – bus enables remote monitoring and efficient management. This 48V 500Ah LiFePO4 Forklift Battery is a cost – effective, durable, and eco – friendly choice for your material handling equipment. Contact us to explore customization and bulk purchasing benefits!

48V LiFePO4 Battery Pricing

What factors influence 48V LiFePO4 forklift battery wholesale pricing?

Pricing is influenced by factors such as battery capacity, order volume, raw material costs (especially lithium), manufacturing scale, and supply chain logistics. Supplier location and battery design complexity also play a role in determining costs.

How does market demand affect LiFePO4 forklift battery costs?

High market demand for LiFePO4 batteries can drive up prices due to limited supply or increased raw material costs. As demand for electric vehicles and green energy solutions grows, battery prices may fluctuate based on these market dynamics.

What are regional price variations for 48V LiFePO4 batteries?

Regional price variations depend on local supply chains, tariffs, taxes, and availability of raw materials. Manufacturers in regions with lower production costs or high demand may offer more competitive pricing compared to others.

How do LiFePO4 batteries compare to lead-acid in pricing?

LiFePO4 batteries generally have a higher upfront cost than lead-acid batteries. However, their longer lifespan, faster charging times, and reduced maintenance needs make them more cost-effective over time.

What bulk order discounts apply to forklift battery wholesale?

Bulk order discounts for forklift batteries are typically based on order volume. Larger orders often receive discounts ranging from 5% to 20%, depending on the supplier and specific battery model being purchased.

How do tariffs impact global LiFePO4 battery wholesale prices?

Tariffs on raw materials like lithium or finished LiFePO4 batteries can increase global prices. These costs are often passed down the supply chain, raising wholesale prices in regions affected by trade tariffs.

LiFePO4 for Warehouse Equipment

What are LiFePO4 battery advantages for warehouse equipment?

LiFePO4 batteries offer advantages like long lifespan, fast charging, and high energy density. They require minimal maintenance, improve operational efficiency, and reduce downtime, making them ideal for warehouse equipment like forklifts and AGVs.

Why choose LiFePO4 over other lithium batteries for durability?

LiFePO4 batteries offer superior thermal stability, safety, and longevity compared to other lithium chemistries. They handle higher charge and discharge cycles, making them more durable and cost-effective for demanding warehouse environments.

How to maintain LiFePO4 batteries in warehouse equipment?

Maintenance for LiFePO4 batteries is minimal but should include regular charging cycle monitoring, ensuring terminals are clean and free from corrosion, and avoiding deep discharges. Proper storage and ventilation also help prolong their lifespan.

What is the lifespan of LiFePO4 batteries in heavy-duty use?

LiFePO4 batteries typically last between 2,000 to 5,000 charge cycles in heavy-duty use, depending on factors like operational conditions, charging habits, and maintenance practices.

What safety standards apply to LiFePO4 batteries in warehouses?

LiFePO4 batteries used in warehouses must meet safety standards such as UL 2580, IEC 62133, and UN 38.3. These standards ensure the batteries’ safety in terms of performance, shipping, and usage under various conditions.

How do LiFePO4 batteries compare to lead-acid in warehouses?

LiFePO4 batteries outlast lead-acid batteries, require less maintenance, and offer faster charging times. They are also safer, with built-in thermal and overcharge protection, making them a superior choice for warehouse environments.

500-Hour Lithium Forklift Batteries

What are 500-hour lithium forklift battery benefits?

500-hour lithium forklift batteries offer long-lasting power and high efficiency. Their extended life cycle ensures fewer replacements, lower operating costs, and improved performance in heavy-duty industrial settings.

How do lithium forklift batteries compare to lead-acid?

Lithium forklift batteries provide faster charging, longer lifespan, and require less maintenance compared to lead-acid batteries. They also offer better energy efficiency, reducing the need for frequent replacements and downtime.

How to maintain 500-hour lithium forklift batteries?

500-hour lithium forklift batteries require minimal maintenance. Regular monitoring of charge cycles, terminal cleaning, and ensuring proper ventilation are key maintenance practices. Avoiding deep discharges and overcharging also helps preserve battery life.

Are 500-hour lithium batteries cost-effective long-term?

Yes, 500-hour lithium batteries are cost-effective in the long run. Their longevity, low maintenance, and higher efficiency compared to lead-acid batteries offset the initial higher purchase cost, making them more affordable over time.

What certifications ensure reliable lithium battery suppliers?

Reputable lithium battery suppliers should have certifications such as UL 2580, CE, ISO 9001, and UN 38.3. These certifications ensure the supplier’s compliance with safety standards and manufacturing quality.

What industries use 500-hour lithium forklift batteries?

Industries such as logistics, warehousing, manufacturing, and retail use 500-hour lithium forklift batteries due to their efficiency, reduced maintenance, and high performance in heavy-duty applications.

Custom LiFePO4 Forklift Batteries

Benefits of LiFePO4 batteries in electric forklifts?

LiFePO4 batteries provide electric forklifts with superior power density, faster charging, and longer operational hours. They offer a safer, more efficient alternative to traditional lead-acid batteries, reducing downtime and operational costs.

Key factors in designing custom LiFePO4 forklift batteries?

Custom LiFePO4 forklift batteries should consider factors like capacity, voltage, charging speed, and physical dimensions to match specific forklift requirements. Thermal management, safety features, and compatibility with charging systems are also important.

How to maintain custom LiFePO4 batteries for forklifts?

Maintenance for custom LiFePO4 forklift batteries involves regular charge cycle monitoring, ensuring terminals are clean, and avoiding extreme temperatures. Proper storage and avoiding deep discharges help maintain battery longevity.

LiFePO4 vs lead-acid batteries for forklifts performance?

LiFePO4 batteries outperform lead-acid in terms of lifespan, charging time, energy efficiency, and safety. They provide consistent power throughout usage, while lead-acid batteries experience performance drops over time.

Safety standards for LiFePO4 batteries in forklifts?

LiFePO4 forklift batteries must adhere to safety standards like UL 2580, CE, and IEC 62133, ensuring they are safe for operation, transportation, and use in industrial environments, minimizing risks such as thermal runaway or overcharging.

Cost-effectiveness of custom LiFePO4 forklift batteries?

Custom LiFePO4 forklift batteries are cost-effective in the long term due to their extended lifespan, faster charging, and reduced maintenance. While the initial investment is higher, these batteries provide lower total cost of ownership over time.

48V Lithium Industrial Batteries

What are key features of 48V lithium industrial batteries?

48V lithium industrial batteries offer high energy density, fast charging, and long operational life. They provide consistent power and require minimal maintenance, making them ideal for heavy-duty industrial applications such as forklifts and automated machinery.

How does 48V lithium enhance machinery performance?

48V lithium batteries improve machinery performance by offering high power output, faster charging, and a stable voltage, allowing machinery to run more efficiently and reducing downtime for recharging or maintenance.

What industries use high-performance 48V lithium batteries?

High-performance 48V lithium batteries are used in industries such as logistics, manufacturing, warehousing, and material handling, powering electric forklifts, AGVs, and other heavy-duty equipment that require reliable and consistent power.

What safety standards govern 48V industrial lithium batteries?

48V industrial lithium batteries must meet safety standards such as UL 2580, IEC 62133, and UN 38.3 to ensure safe operation, including protection against overcharging, short circuits, and thermal runaway.

How does 48V lithium compare to lead-acid batteries?

48V lithium batteries offer several advantages over lead-acid, including faster charging times, longer lifespan, and higher efficiency. They also require less maintenance and provide consistent power output, improving overall operational productivity.

What charging methods optimize 48V lithium battery lifespan?

To optimize the lifespan of 48V lithium batteries, use appropriate chargers that match the battery’s specifications, avoid deep discharges, and maintain proper charging cycles. Storing the battery in a cool, dry place also helps preserve its longevity.

LiFePO4 for Logistics Equipment

What are key criteria for selecting LiFePO4 battery suppliers?

Key criteria for selecting LiFePO4 battery suppliers include certifications (such as UL and CE), reputation, experience, production capacity, and customer support. Suppliers should offer reliable products with a focus on safety and quality.

How do LiFePO4 batteries enhance logistics equipment performance?

LiFePO4 batteries enhance logistics equipment performance by providing consistent power, reducing charging times, and requiring less maintenance. Their long lifespan and efficiency make them ideal for high-use equipment like forklifts, AGVs, and other material handling systems.

Which industries prioritize LiFePO4 batteries for material handling?

Industries such as logistics, warehousing, manufacturing, and retail prioritize LiFePO4 batteries for material handling due to their high efficiency, long lifespan, and reduced maintenance requirements, making them ideal for continuous operation.

What certifications ensure LiFePO4 battery safety in logistics?

LiFePO4 batteries used in logistics must meet certifications such as UL 2580, CE, ISO 9001, and UN 38.3 to ensure they meet safety and quality standards for transportation and use in industrial environments.

How to maintain LiFePO4 batteries in material handling systems?

LiFePO4 batteries in material handling systems require minimal maintenance, but periodic checks on battery charge levels, terminal cleanliness, and proper charging cycles are recommended. Ensure proper storage conditions and avoid deep discharges.

What innovations drive LiFePO4 battery efficiency in logistics?

Innovations such as advanced battery management systems (BMS), improved thermal management, and enhanced charging protocols are driving greater efficiency in LiFePO4 batteries, improving performance and extending lifespan in logistics and material handling systems.