Description

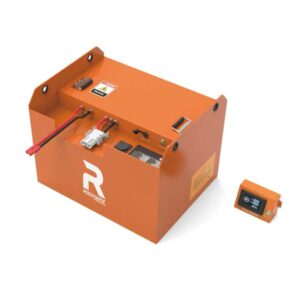

Our lithium battery manufacturer offers the 38.4V 690Ah LiFePO4 Forklift Battery, a high – performance solution for OEM and wholesale buyers. It provides long – lasting power for material handling equipment.

Key Features

- High Energy Output: With a 690Ah capacity and 26.5kWh energy output, it extends heavy – duty operational hours.

- Exceptional Discharge Performance: Delivers 320A continuous discharge and 480A peak discharge for 5 seconds to handle tough tasks.

- Long Cycle Life: Offers over 4000 cycles at 80% Depth of Discharge, cutting maintenance and replacement costs.

- Durable & Reliable Construction: Has an IP65 rating for water and dust resistance and a robust metal shell for harsh environments.

- Smart Battery Management System (BMS): Advanced BMS technology for real – time monitoring and optimal battery management, ensuring safety and efficiency.

Product Description

The 38.4V 690Ah LiFePO4 Forklift Battery is crafted for high – demand industrial settings. With a 26.5kWh nominal energy capacity, it’s perfect for forklifts and material – handling vehicles. It’s highly customizable for OEM needs. Its compact size (967 x 515 x 779 mm) and 330 kg weight make it compatible with various forklift models. The continuous 320A and 480A peak discharge make it suitable for heavy lifting. It has over 4000 charge/discharge cycles at 80% DoD, far exceeding traditional lead – acid batteries. The BMS monitors parameters like SOC, voltage, current, and temperature, protecting against overcharging and short – circuits. The IP65 rating and durable metal shell ensure reliable performance in tough conditions.

Benefits for OEM and Wholesale Buyers

For OEM battery customers, our lithium battery is customizable, allowing them to integrate it seamlessly into their products. This flexibility gives them an edge in the market. Wholesale buyers can benefit from the long cycle life and low total ownership costs of our 38.4V 690Ah LiFePO4 Forklift Battery. They can offer reliable products to their clients, enhancing productivity and reducing operational expenses. Our lithium battery manufacturer is committed to providing high – quality, efficient solutions for both OEM and wholesale needs.

Why Choose Our Lithium Batteries

As a lithium battery manufacturer, we focus on innovation and quality. Our batteries are designed with the latest technology to meet the evolving needs of the industrial sector. The combination of high energy output, long cycle life, and advanced BMS makes our lithium batteries a superior choice. Whether you’re an OEM looking to improve your product’s performance or a wholesale buyer aiming to offer reliable batteries, our products are the ideal solution. Contact us today to discuss customization options and bulk purchasing benefits.

36V 700Ah LiFePO4 Forklift Batteries

What applications use 36V 700Ah LiFePO4 batteries?

36V 700Ah LiFePO4 batteries are typically used in high-demand industrial applications such as large forklifts, automated guided vehicles (AGVs), and other heavy-duty material handling equipment. These batteries are ideal for operations in warehouses, distribution centers, and manufacturing plants, where extended runtimes and frequent recharging are essential.

Why choose LiFePO4 over lead-acid for forklifts?

LiFePO4 batteries are preferred over lead-acid batteries in forklifts due to their longer lifespan, faster charging times, lower maintenance requirements, and better energy efficiency. Unlike lead-acid batteries, LiFePO4 batteries don’t require watering, equalization charges, or regular maintenance, reducing operational costs and downtime.

How long to charge a 36V 700Ah LiFePO4 battery?

A 36V 700Ah LiFePO4 battery typically takes around 4-6 hours to fully charge, depending on the charger and the battery’s current state of charge. Some fast-charging technologies can reduce this time, but standard charging times typically range between 4 and 6 hours.

What lifespan does a LiFePO4 forklift battery have?

LiFePO4 forklift batteries typically last between 3,000 and 5,000 charge cycles, which is significantly longer than lead-acid batteries (500-1,000 cycles). The actual lifespan can vary depending on factors like usage, temperature, and maintenance, but the longer cycle life leads to lower total cost of ownership.

Does 36V 700Ah LiFePO4 require regular maintenance?

LiFePO4 batteries have minimal maintenance requirements. Unlike lead-acid batteries, they don’t need watering or equalization charges. Regular maintenance involves checking for any corrosion at the battery terminals, ensuring the battery management system (BMS) is functioning properly, and ensuring that the battery is used within recommended temperature ranges.

Are LiFePO4 forklift batteries resistant to thermal runaway?

Yes, LiFePO4 batteries are highly resistant to thermal runaway, a common issue with other types of lithium-ion batteries. This makes them safer for use in industrial environments. LiFePO4 chemistry inherently has better thermal stability, reducing the risk of fires or explosions in case of overcharging, over-discharging, or damage.

LiFePO4 Battery Suppliers and Features

What certifications should wholesale LiFePO4 battery suppliers have?

Wholesale LiFePO4 battery suppliers should have certifications such as ISO 9001 for quality management, UL 2054 for battery systems, IEC 62133 for battery safety, and UN 38.3 for transportation safety. These certifications ensure that the batteries meet international standards for safety, reliability, and environmental impact.

How to evaluate LiFePO4 battery suppliers for industrial use?

When evaluating LiFePO4 battery suppliers for industrial use, consider factors such as their experience in manufacturing industrial-grade batteries, the quality of their products, compliance with safety certifications, customer support, warranty policies, and their ability to customize solutions for your specific needs. Reviews and case studies from other industrial users can also be helpful.

What are key features of industrial-grade LiFePO4 batteries?

Key features of industrial-grade LiFePO4 batteries include high energy density, long cycle life (3,000–5,000 cycles), safety features such as overcharge and over-discharge protection, temperature stability, and low maintenance requirements. They also typically have a Battery Management System (BMS) for monitoring health and performance.

Do suppliers offer custom LiFePO4 solutions for equipment?

Yes, many LiFePO4 battery suppliers offer custom solutions tailored to specific equipment requirements. This includes designing batteries with the appropriate voltage, capacity, and physical dimensions to fit unique forklift models, as well as offering customizable Battery Management Systems (BMS) to monitor specific needs.

How to ensure LiFePO4 battery longevity in industrial applications?

To ensure LiFePO4 battery longevity in industrial applications, it’s essential to maintain proper charging practices, avoid deep discharges, ensure the battery is not exposed to extreme temperatures, and regularly check the battery management system (BMS) for any issues. Using the right charger and adhering to the manufacturer’s guidelines is key to prolonging battery life.

What trends affect LiFePO4 battery pricing for industrial sectors?

Trends that affect LiFePO4 battery pricing for industrial sectors include the cost of raw materials (such as lithium, phosphate, and iron), technological advancements that reduce production costs, economies of scale, and increased demand for clean energy solutions. Additionally, global supply chain factors, such as trade regulations and transportation costs, can influence pricing.

LiFePO4 Forklift Battery Manufacturers and Innovations

Top LiFePO4 forklift battery manufacturers in China?

Top manufacturers of LiFePO4 forklift batteries in China include companies like BYD, CATL (Contemporary Amperex Technology Co. Ltd.), and CALB (China Aviation Lithium Battery Co., Ltd.). These companies are known for their large-scale production and advanced technology in LiFePO4 battery systems for industrial applications.

Benefits of high-capacity LiFePO4 forklift batteries?

High-capacity LiFePO4 forklift batteries, like 36V 700Ah, provide longer runtime, improved operational efficiency, and greater energy storage. These batteries are ideal for heavy-duty material handling applications, offering faster charging times and reduced downtime. They also have a longer lifespan, reducing the frequency of battery replacements and maintenance.

Certifications for Chinese LiFePO4 battery manufacturers?

Chinese LiFePO4 battery manufacturers often hold certifications like ISO 9001 for quality management, UL 2054 for battery systems, IEC 62133 for safety, and UN 38.3 for transportation. These certifications ensure that the batteries meet international standards and are safe for use in industrial applications.

How do Chinese manufacturers ensure battery longevity?

Chinese LiFePO4 battery manufacturers ensure longevity by using high-quality raw materials, advanced manufacturing processes, and robust quality control measures. They also implement battery management systems (BMS) to monitor battery health, ensuring safe operation and optimizing charge cycles for longer battery life.

Comparing Chinese vs global LiFePO4 battery suppliers?

Chinese LiFePO4 battery suppliers are typically more cost-competitive due to economies of scale and local material sourcing. They offer high-quality batteries at a lower cost compared to global suppliers. However, some global suppliers may have better-established support networks and more rigorous quality control, especially for specific high-end or custom applications.

Innovations in China’s LiFePO4 forklift battery technology?

Innovations in China’s LiFePO4 forklift battery technology include advancements in energy density, faster charging capabilities, improved battery management systems (BMS), and enhanced thermal management systems. These innovations result in batteries that offer greater efficiency, longer lifespans, and better overall performance in industrial environments.

LiFePO4 Battery Solutions for Warehouse Machinery

Why choose LiFePO4 batteries for warehouse machinery?

LiFePO4 batteries are a great choice for warehouse machinery due to their long lifespan, faster charging times, and low maintenance requirements. They also provide high energy density and operate efficiently in demanding environments. Additionally, LiFePO4 batteries are safe, environmentally friendly, and offer reduced operational costs.

What are custom LiFePO4 solutions’ key advantages?

Custom LiFePO4 solutions are tailored to meet the specific needs of warehouse machinery, offering optimal energy storage, fast charging, and integration with existing equipment. Customization allows for batteries that perfectly fit the physical dimensions of machinery, ensuring maximum performance and efficiency while reducing downtime.

How to design LiFePO4 batteries for heavy-duty equipment?

To design LiFePO4 batteries for heavy-duty equipment, it’s essential to consider the required voltage, capacity, and physical dimensions. Additionally, the battery management system (BMS) should be customized to monitor critical factors such as temperature, charge cycles, and battery health. High-capacity cells, robust thermal management, and safety features must also be prioritized for heavy-duty applications.

What safety standards apply to warehouse LiFePO4 systems?

Safety standards for warehouse LiFePO4 systems include compliance with UL 2054 (battery systems), IEC 62133 (safety for portable batteries), and UN 38.3 (transportation of lithium batteries). These standards ensure the batteries are safe to use in warehouse environments, minimizing risks like overcharging, overheating, and short-circuiting.

How do LiFePO4 batteries improve machinery runtime efficiency?

LiFePO4 batteries improve machinery runtime efficiency by offering a higher energy density compared to traditional lead-acid batteries. This means they can store more energy in the same space, providing longer operational times without frequent recharges. Their fast-charging capabilities also allow for minimal downtime between shifts.

What maintenance optimizes LiFePO4 battery lifespan in warehouses?

To optimize the lifespan of LiFePO4 batteries in warehouses, regular maintenance should include ensuring the battery is charged within recommended ranges, avoiding deep discharges, inspecting the battery management system (BMS), and monitoring temperature conditions. Additionally, periodic checks of battery terminals for corrosion and ensuring proper storage conditions will help extend the battery’s life.

Bulk Ordering LiFePO4 Forklift Batteries

What are the benefits of bulk ordering 700Ah forklift batteries?

Bulk ordering 700Ah forklift batteries offers significant cost savings due to volume discounts. It also ensures consistent battery performance across a fleet of forklifts and simplifies procurement, maintenance, and replacement scheduling. Bulk purchasing reduces lead times and helps businesses maintain stock levels for uninterrupted operations.

How does 700Ah capacity impact forklift performance?

A 700Ah capacity significantly improves forklift performance by providing extended runtimes, reducing the frequency of recharging, and supporting more demanding tasks. The higher capacity ensures that heavy-duty forklifts can operate for longer periods without losing power, which is ideal for high-traffic or continuous-use applications in warehouses or manufacturing facilities.

What factors affect lithium iron phosphate battery lifespan?

Factors affecting LiFePO4 battery lifespan include temperature conditions, charge and discharge cycles, maintenance practices, and usage patterns. Keeping the battery in optimal operating temperatures, avoiding deep discharges, and following proper charging protocols can significantly extend its lifespan.

How to evaluate suppliers for bulk LiFePO4 battery purchases?

When evaluating suppliers for bulk LiFePO4 battery purchases, consider factors such as product quality, certifications, warranty terms, after-sales support, and the ability to meet delivery deadlines. Supplier reliability, cost-effectiveness, and ability to provide ongoing support and services, such as installation and maintenance, are also important.

What safety standards apply to lithium forklift batteries?

Safety standards for lithium forklift batteries include UL 2054 for battery systems, IEC 62133 for battery safety, UN 38.3 for transportation, and ISO 9001 for quality management. These certifications ensure the batteries are safe, reliable, and meet international safety regulations for use in industrial forklift applications.

How to optimize charging cycles for 700Ah LiFePO4 batteries?

To optimize charging cycles for 700Ah LiFePO4 batteries, avoid deep discharges and ensure the battery is not constantly charged to 100%. Use chargers designed for LiFePO4 batteries, which help ensure proper charging and prevent overcharging or undercharging. Implementing scheduled maintenance and monitoring through the battery management system (BMS) will also help maintain the battery’s health.